Are you looking for the perfect aluminum profiles for your next transportation project?

The 40×80 aluminum baffle ceiling is a top choice for airports and high-speed railway stations, offering modern aesthetics, excellent acoustic performance, and durability. These features make them ideal for high-traffic environments, ensuring that both functionality and design are achieved.

In this blog post, we will delve deeper into the benefits of aluminum profiles in these settings, explore customization options, and provide insights on how to choose the right materials for your needs.

What are the key characteristics of aluminum profiles for transportation hubs?

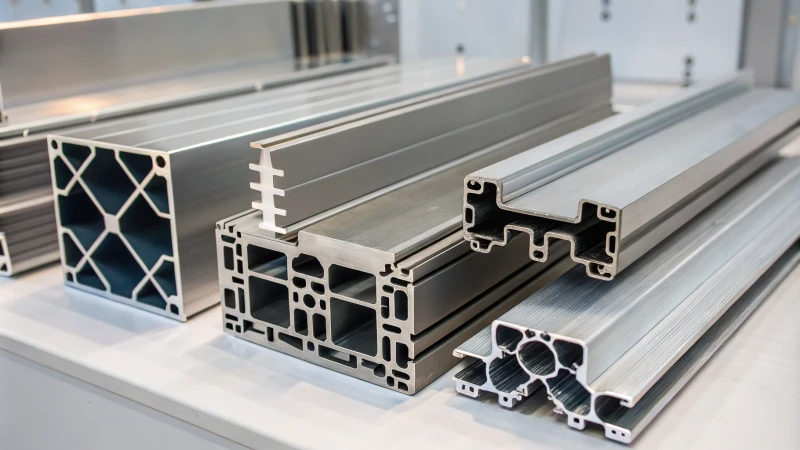

Aluminum profiles play a crucial role in the construction of transportation hubs, offering a blend of strength, durability, and versatility. But what are their key characteristics?

The key characteristics of aluminum profiles for transportation hubs include high strength-to-weight ratio, corrosion resistance, design versatility, lightweight nature, excellent thermal conductivity, and sustainability through recyclability.

Strength and Durability

Aluminum profiles are known for their high strength-to-weight ratio, making them ideal for transportation hubs where structural integrity is critical.

They can withstand heavy loads while remaining lightweight, which is essential for reducing the overall weight of structures like bridges and roofs.

For instance, the use of aluminum in structural applications can significantly enhance the lifespan of facilities while minimizing the need for frequent maintenance.

Corrosion Resistance

One of the standout characteristics of aluminum profiles is their inherent resistance to corrosion. This feature is particularly advantageous in environments where exposure to moisture and varying weather conditions is common, such as airports and train stations.

Aluminum forms a protective oxide layer when exposed to air, preventing further oxidation. As a result, projects that utilize aluminum profiles tend to have lower maintenance costs over time. A comparison chart highlighting aluminum’s resistance to various environmental factors can illustrate this benefit effectively.

| Environmental Factor | Aluminum Resistance | Steel Resistance |

|---|---|---|

| Moisture | High | Moderate |

| UV Radiation | High | Low |

| Salt Spray | High | Low |

Versatility in Design

Aluminum profiles offer exceptional versatility in design, allowing architects and engineers to create innovative and aesthetically pleasing structures. They can be easily extruded into various shapes and sizes to meet specific project requirements.

This adaptability enables the incorporation of unique architectural features in transportation hubs, contributing to their visual appeal while meeting functional needs. Designers can explore aluminum profile customization options that cater to different projects and branding.

Lightweight Nature

The lightweight property of aluminum profiles not only aids in ease of handling during installation but also reduces the load on supporting structures. This characteristic is crucial in transportation hubs where large spans are required without compromising on safety.

In large-scale projects, such as railway stations, utilizing lighter materials can lead to cost savings in terms of foundation work and overall structural requirements. For more details, visit our section on benefits of lightweight materials.

Thermal Conductivity

Aluminum profiles exhibit excellent thermal conductivity, making them effective in managing temperature variations within buildings. This property is particularly beneficial in transportation hubs that require controlled environments for passenger comfort.

By incorporating thermal breaks into aluminum profile designs, engineers can improve energy efficiency while ensuring thermal comfort in high-traffic areas. Explore our resource on energy-efficient materials for further insights.

Environmental Sustainability

Lastly, aluminum is a highly recyclable material, which aligns with modern sustainability practices. Transportation hubs often prioritize eco-friendly construction methods, making aluminum profiles an attractive option.

The ability to recycle aluminum without loss of quality makes it a sustainable choice for infrastructure projects. More information about sustainable building materials can be found here.

How do aluminum baffle ceilings improve acoustic comfort in busy environments?

Discover how aluminum baffle ceilings can transform noisy environments into spaces of acoustic comfort and aesthetic beauty.

Aluminum baffle ceilings enhance acoustic comfort by absorbing sound waves and reducing reverberation, making busy environments like airports and schools more pleasant for occupants.

Understanding Acoustic Comfort

Acoustic comfort refers to the quality of sound within a space, significantly impacting how people experience that environment. In busy places like airports or schools, noise can be overwhelming. Aluminum baffle ceilings help mitigate this by absorbing and diffusing sound effectively. This results in a more pleasant atmosphere for both visitors and staff.

How Aluminum Baffle Ceilings Work

Aluminum baffle ceilings utilize a strategic arrangement of baffles that promote sound absorption and diffusion. The unique design creates a gap between the baffles, allowing sound waves to penetrate the ceiling space, where they can be absorbed rather than reflected back into the room.

For instance, studies show that spaces treated with baffle ceilings can reduce reverberation time significantly, which is crucial in areas with high foot traffic.

| Feature | Impact on Acoustic Comfort |

|---|---|

| Spacing of Baffles | Reduces echo and reverberation |

| Material Properties | High absorption coefficient for sound |

| Customization Options | Tailored to specific acoustic needs |

Real-World Applications

In environments like airport terminals, where multiple announcements and conversations happen simultaneously, aluminum baffle ceilings can drastically improve sound clarity. The careful design allows for optimal sound management, ensuring that important information is heard clearly without excessive background noise interference.

Likewise, in educational settings, these ceilings aid concentration by minimizing disruptive sounds. Studies indicate that classrooms with baffle ceilings see improved student engagement and academic performance.

Benefits Beyond Acoustic Comfort

While the primary benefit of aluminum baffle ceilings is their acoustic performance, they also enhance aesthetic appeal and light diffusion. This dual functionality makes them an attractive choice for architects and designers aiming to create visually pleasing and acoustically comfortable spaces.

Their modularity facilitates easy installation and maintenance, making them ideal for busy environments where disruptions need to be minimized.

Additional Considerations

When selecting aluminum baffle ceilings, consider factors such as:

- Material Durability: Aluminum is resistant to corrosion and UV degradation, ensuring longevity in high-usage areas.

- Customization: Options in color, finish, and layout can help align the ceiling design with branding or architectural themes.

- Cost vs. Quality: While initial investments might be higher, the long-term benefits in comfort and durability often outweigh these costs.

To learn more about how to incorporate aluminum baffle ceilings into your design projects for improved acoustic comfort, check out this comprehensive guide.

What customization options are available for aluminum profiles in design projects?

Customization of aluminum profiles opens up a world of possibilities for design projects. Explore the various options available to enhance both functionality and aesthetics in your upcoming designs.

Aluminum profiles offer extensive customization options including shapes, sizes, surface finishes, and modular configurations, allowing tailored solutions that meet specific design needs in construction and manufacturing projects.

Understanding Customization Options for Aluminum Profiles

When it comes to aluminum profiles, customization plays a pivotal role in aligning the materials with project specifications. Different projects have unique needs, and here’s how customization can enhance aluminum profiles:

-

Shapes and Sizes:

- Aluminum profiles can be extruded into various shapes such as L, T, U, and more. Custom dimensions allow designers to create profiles that fit specific structural or aesthetic requirements. This flexibility is crucial for projects where conventional sizes are inadequate.

- For example, a project requiring support beams might benefit from a custom I-beam profile for enhanced strength and weight distribution. Explore custom shapes.

-

Surface Finishes:

- Surface treatments like anodizing, powder coating, and brushed finishes not only improve aesthetics but also enhance durability and corrosion resistance.

- Anodizing adds a protective layer while allowing for color customization, making it suitable for high-visibility areas. Powder coating provides an extensive color palette and is ideal for outdoor applications.

- Below is a comparison of finishes:

Finish Type Benefits Applications Anodizing Durable, color options Architectural features Powder Coating Variety of colors, UV resistant Outdoor furniture Brushed Aesthetic appeal, texture Decorative elements -

Modular Configurations:

- Modular designs facilitate ease of installation and adaptation in projects. For instance, interlocking profiles can simplify assembly in complex structures. This adaptability is particularly useful in areas requiring frequent updates or expansions.

- Modular systems allow for reconfiguration without needing entirely new materials, which can save costs and time. Learn more about modular designs.

-

Custom Lengths:

- Aluminum profiles can be ordered in custom lengths to minimize waste and ensure a perfect fit for specific applications. This precision reduces the need for additional cutting on-site, enhancing efficiency.

- Working with local suppliers can also reduce shipping costs and carbon footprints, which aligns with sustainable practices many designers prioritize today. Check out local suppliers.

-

Integrated Features:

- Profiles can be designed to include integrated features such as cable management channels or mounting brackets, which streamline installation processes and improve functionality.

- Such innovations can significantly enhance the user experience by minimizing clutter and optimizing space usage.

By considering these customization options, designers can ensure their aluminum profiles not only meet structural demands but also complement the overall aesthetics of their projects effectively. This approach not only enhances functionality but also resonates well with sustainability goals that many companies like Sinoextrud advocate for.

How to select reliable suppliers for high-quality aluminum materials?

Finding reliable suppliers for high-quality aluminum materials is critical for any successful project. Here’s how to navigate the selection process effectively.

To select reliable suppliers for high-quality aluminum materials, define your requirements, evaluate supplier experience, assess quality control measures, consider sustainability practices, and analyze customer support options.

Understand Your Requirements

Before embarking on the journey of selecting a supplier, it’s crucial to define your specific needs for aluminum materials. Consider factors such as:

- Type of Aluminum: Identify the grade and specifications required for your projects.

- Quantity: Determine how much material you need and whether your supplier can meet that demand.

- Delivery Schedule: Assess the timeline for your project to ensure timely delivery of materials.

Understanding these aspects will allow you to narrow down suppliers who can meet your unique requirements effectively. For more on material specifications, check out this resource on aluminum grades.

Evaluate Supplier Experience

Experience is a key indicator of a supplier’s reliability. When evaluating potential suppliers, consider the following:

| Criteria | Importance Level | Questions to Ask |

|---|---|---|

| Years in Business | High | How long have you been supplying aluminum? |

| Industry Knowledge | High | What industries do you specialize in? |

| Client Testimonials | Medium | Can you provide references from past clients? |

Supplier experience often translates to better quality control and understanding of client needs. You may want to explore customer reviews to gauge their reputation in the market.

Assess Quality Control Measures

A reliable supplier should have stringent quality control measures in place. Look for suppliers who:

- Conduct Regular Testing: Inquire about their testing protocols for aluminum materials.

- Certifications: Check if they have industry-recognized certifications, such as ISO standards.

- Traceability: Ensure they can trace the origin of their materials and provide documentation when needed.

These factors will help guarantee the quality and consistency of the materials you receive. For further insights, see this guide on quality assurance in manufacturing.

Consider Sustainability Practices

With increasing environmental awareness, it’s important to evaluate suppliers based on their sustainability practices. Questions to consider include:

- Material Sourcing: Are the aluminum materials sourced responsibly?

- Recycling Policies: Do they have programs for recycling and waste reduction?

- Energy Efficiency: What measures do they take to minimize energy consumption during production?

A supplier’s commitment to sustainability can enhance your brand’s reputation while ensuring compliance with regulations. Learn more about sustainable practices in the industry through this sustainability resource.

Analyze Customer Support and Communication

Strong communication and support are vital when working with suppliers. Evaluate potential suppliers by:

- Responsiveness: How quickly do they respond to inquiries?

- Support Availability: Do they offer support during and after procurement?

- Problem Resolution: How do they handle issues or complaints?

Reliable customer support ensures that you can address any concerns promptly, maintaining smooth operations. For tips on effective communication with suppliers, check out this article on supplier relationship management.

What safety and performance standards should aluminum profiles meet in airports?

In airports, aluminum profiles must meet stringent safety and performance standards to ensure passenger safety and operational efficiency. What are these essential standards?

Aluminum profiles used in airports must adhere to safety standards like fire resistance (NFPA) and structural integrity (IBC), as well as performance criteria regarding durability, thermal insulation, and regulatory compliance with agencies like the FAA.

Understanding Safety Standards in Airport Construction

When it comes to airport infrastructure, safety is paramount. Aluminum profiles used in airports must comply with strict regulations and standards set forth by various authorities. Key safety standards include:

-

Fire Safety: Aluminum materials should meet fire resistance classifications as outlined by the National Fire Protection Association (NFPA). This ensures that in the event of a fire, the structural integrity of the materials remains intact, allowing for safe evacuation.

-

Structural Integrity: The profiles must adhere to load-bearing requirements defined by the International Building Code (IBC). This ensures that the materials can withstand environmental stresses, such as wind loads and seismic activity, which are critical in airport locations.

Performance Standards for Aluminum Profiles

Performance standards dictate how well aluminum profiles function under operational conditions. They include:

-

Durability: Materials must resist corrosion and wear, especially in high-traffic areas where they are exposed to harsh conditions. This is often assessed through testing that simulates prolonged exposure to moisture and contaminants.

-

Thermal Performance: Aluminum profiles should have insulating properties that contribute to energy efficiency within airport terminals. The performance is evaluated based on U-values, which measure the rate of heat transfer.

| Standard | Description |

|---|---|

| NFPA 701 | Fire tests for flame propagation in textiles and films. |

| ASTM E84 | Standard test for surface burning characteristics of building materials. |

| IBC | Regulations ensuring structural safety and performance. |

Compliance with Regulatory Agencies

Compliance with agencies like the Federal Aviation Administration (FAA) is crucial. The FAA provides guidelines that help ensure the safety and effectiveness of airport facilities.

-

Guidelines for Airport Infrastructure: The FAA mandates that all materials used in airport construction must meet specific performance criteria to ensure passenger safety.

-

Regular Inspections: Airports are subject to routine inspections to ensure that all installed materials comply with the latest safety standards.

Customization and Environmental Considerations

Given the diverse requirements of airport design, customization of aluminum profiles plays a significant role:

-

Adaptability: Aluminum profiles can be tailored to meet unique architectural designs while still complying with safety and performance standards.

-

Sustainability: Using recycled aluminum can help airports achieve sustainability goals while ensuring compliance with environmental regulations.

By focusing on these standards and considerations, aluminum profiles can effectively contribute to safer and more efficient airport environments, facilitating smooth operations and enhancing passenger experience.

For further details on specific compliance standards, consider checking the resources available at FAA Guidelines or Building Code Requirements.

Conclusion

Explore the benefits of aluminum profiles in transportation hubs like airports and rail stations, focusing on durability, acoustic comfort, design versatility, and sustainability.