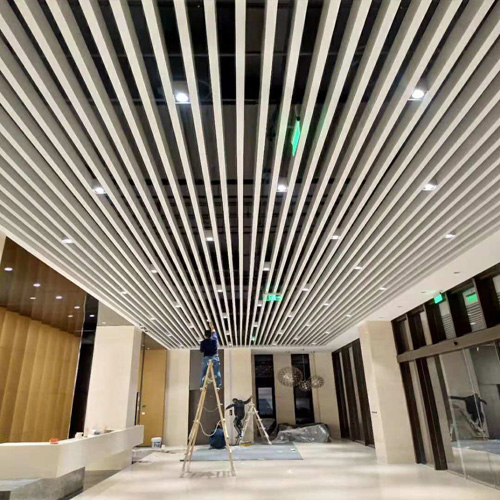

Installing Aluminum Baffle Ceilings1 can be challenging without proper guidance. A poor installation can lead to costly repairs and compromised aesthetics. This article is a step-by-step experience that led me to an installation success story.

Aluminum Baffle Ceilings2 are highly valued for their acoustic enhancement and modern appearance. Through this article I will guide you through the effective installation of aluminum baffle ceilings.

I believe that by reading on, you will understand why aluminum baffle ceilings are ideal for modern interior design, especially in large commercial spaces.

1, Let me tell you what the purpose of putting in a baffled ceiling is.

Baffled ceilings serve both a functional and aesthetic purpose. It improves the sound quality of large spaces where echoes can create noise problems. By absorbing sound waves, baffle ceilings enhance the acoustics of places like offices, airports and auditoriums, resulting in a more comfortable environment.1

Visually, baffled ceilings add depth and rhythm, making spaces seem more open and architecturally dynamic. They can be customized to fit a variety of design needs, whether bold or minimalist. Additionally, they hide structural elements such as the HVAC system while keeping maintenance accessible, which I really like.

Finally, the open design of the baffled ceiling promotes better airflow and lighting, contributing to energy efficiency and comfort.

(1) First of all let me tell you what is an aluminum baffle ceiling?

Aluminum baffle ceilings consist of lightweight, corrosion-resistant panels suspended from the ceiling using a track or bracket system. These panels, or baffles, are customizable in length, width, and height. In commercial settings, aluminum baffle ceilings are known for their durability, low maintenance, and modern aesthetics.

Their resistance to corrosion and fire makes them suitable for high traffic or high risk areas. Customization options include a variety of colors, textures and finishes to complement interior design. Manufacturers like Forever Aluminum offer OEM and ODM services for custom profiles, and I’ve gone through it to help me a lot.

Aluminum baffle ceiling is widely used because it has excellent corrosion and fire resistance.True

The light weight and corrosion-resistant surface of the aluminum baffle make it capable of being widely used.

(2)How thick is the aluminum stopper?

Aluminum baffles are typically between 1mm and 2mm thick, depending on the specific project requirements. Thicker baffles (approximately 2mm) are required for large commercial spaces where structural integrity is required. They can withstand wear and tear and provide a visually striking ceiling.2

Instead, thinner baffles (approximately 1mm) are suitable for residential or light commercial applications where weight and cost efficiency are priorities. While they maintain a minimalist aesthetic, thinner baffles still offer excellent sound absorption and design flexibility.

I went with the 1mm thickness for a western style dining room I installed this year and was quite happy with the results.

Aluminium baffle ceiling thickness with 1.0mm thick, more lightweight and cost-effectiveTrue

2.0mm thick aluminium baffle ceiling is too heavy and costly, 1.0mm thick is more suitable to be installed on the ceiling..

1.0mm thick aluminium baffle ceiling is easy to deform because of its thinness.False

Because of the hardness of the aluminium profile material is very hard, there is no impact generally will not be easily deformed.

Choosing the proper thickness will also affect the spacing between baffles. Thicker options allow for wider gaps, creating dramatic visual effects, while thinner options are better suited for tighter configurations.

2, I use practice to show you how to install a metal baffle ceiling

Installing an aluminum baffle ceiling requires careful planning and precision. Follow the steps below for a successful installation:

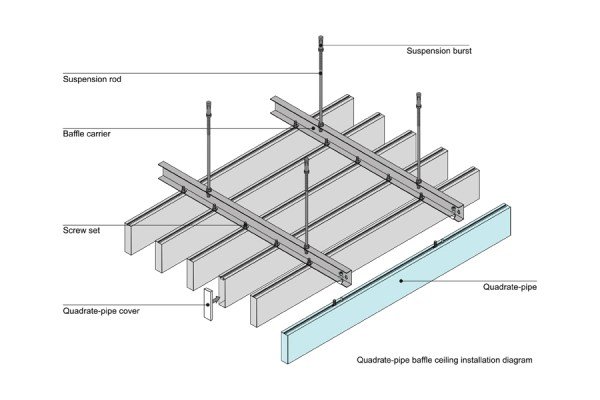

First of all, let’s understand the aluminum baffle ceiling structure construction3

From the above picture can be seen to complete a complete ceiling materials needed are: pull the explosion, boom, the main keel, vice keel, screw links, square through Material composition4

Step 1: Pre-installation preparation: clearing the workspace。

Gather all necessary tools: tape measure, hanging wire, brackets, aluminum stops and fasteners. Read the specific installation instructions provided by the manufacturer.

Tools required

Step 2. Measure and Mark: Use a tape measure to determine and mark the installation position of the baffle. Make sure measurements are accurate and evenly spaced. Double-check measurements to avoid errors during installation. A laser level can help ensure proper placement.

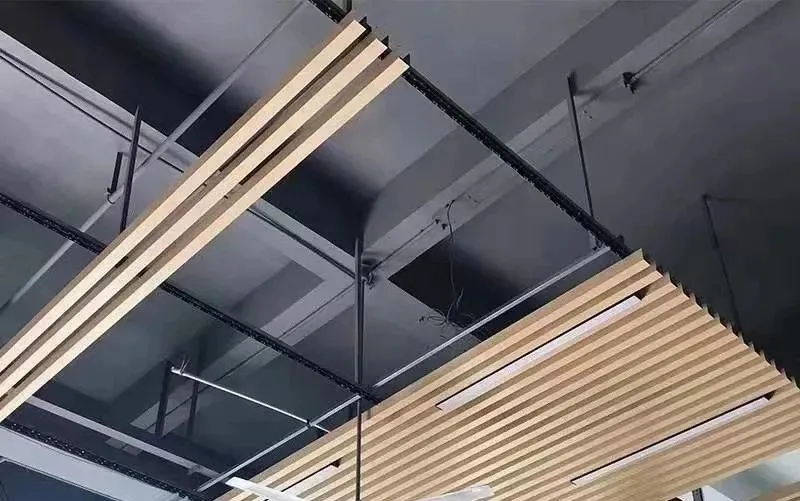

Step 3.Installation of Suspension System: Fix the suspension wires or brackets to the ceiling according to your marking. The system supports aluminum baffles. Ensure that the suspension system is securely fastened; any misalignment may result in improper installation.

Step 4.Attaching the anti-baffle: Attach the aluminum baffle to the bracket or rail. Make sure each baffle is positioned correctly and at the desired height. Tighten all fasteners to prevent movement over time.

Step 5.Final adjustment and finished touch:After all the baffles are in place, step back and check your work. Make final adjustments to ensure spacing and alignment. This is also the time to check that the ceiling looks balanced and visually appealing.

Step 6. Post-installation Inspection: Check for loose fittings or misaligned panels. Verify that the baffle ceiling meets the acoustical and design specifications for the project. A thorough inspection will help prevent future problems and ensure the longevity of the installation.

By following these steps, you can successfully install an aluminum baffle ceiling that improves aesthetic and acoustic performance.

Conclusion

When choosing aluminium baffle ceiling materials, we should not only consider their thickness and specifications, but also pay attention to the quality of accessories and installation methods. Reasonable matching can effectively improve the installation efficiency and ensure the solidity and beauty of the ceiling.